What Are Electroformed Badges?

Electroformed badges are premium metal logos created by building metal layer by layer rather than cutting or stamping it. This process allows for extremely fine detail, crisp edges, and smooth surfaces that traditional manufacturing methods cannot achieve. Electroforming is commonly used for luxury branding applications where appearance, finish appearance and visual precision are critical.

Types Of Electroformed Badges

Discover what makes each category special

2D Electroformed Badges

Custom designed coins for any occasion

- Premium quality materials

- Custom designs available

- Fast turnaround time

3D Electroformed Badges

Professional badges for every need

- Durable construction

- Multiple attachment options

- Bulk discounts available

Product Details

Materials

The material utilized to fabricate the badges will be dependent on the application and design, but all electroforming is done using:

- Nickel - Nickel electroforming is the most common.

- Copper - Electroforming copper is also used, but it is not as common.

If a thicker badge is desired we can utilize aluminum or ABS plastic as a base.

Surface Process

Unlike other manufacturing methods, most finishes and textures are applied directly on the tooling. Additional finishes and treatments can be applied to the badge after the process is complete. Enhance your product branding by utilizing our large range of finish and coating options:

- Physical Vapor Deposition (PVD)

- Diamond Cut

- Plating - Chrome & Gold

- Painting

- Satin, matte or polished finish

- Antiquing

- Hairline

- Custom effects

- More!

Artwork/Engineering Drawings

These are commonly known as source or vector files. In short, vector files allow us to turn your design concepts into tangible badges.

If you do not have artwork, don't worry. Our designers can help convert your design into production ready drawings. It is best if you can provide us with pictures or sketches of your design. We do the rest, free of charge to you.

We have emblem designers who can design a badge from scratch, but there is a fee for this service.

Quick Quote

In order for us to provide you with the quickest possible quote, it is best to include the following information in your submission:

- Artwork

- Quantity

- Dimensions (Height x Length x Width) - If you're not too sure about the thickness our engineers can help.

- Fitting

- Any special request

If you do not have all this information we can still help. Submit as much information as possible.

All Reward, No Risk Guarantee

Enduring luxury, the magic of electroformed badges

A beautifully designed badge evokes an instant sense of trust, admiration, and desire in the consumer's heart and mind. It’s that magnetic moment where the shine, precision, and elegance of the emblem creates a feeling of preeminence and exclusivity, making them believe they’re experiencing something truly special. This emotional connection turns your product into more than just an item. Why electroforming?

- Precision: Every curve, every line—electroforming’s precision redefines excellence.

- Durability: Corrosion resistance ensures your design stands the test of time, enduring the elements without losing its brilliance.

- Customization: Turn your wildest ideas into reality with endless design options.

- Lightweight: Less weight, more impact—the perfect balance.

Mix different materials together for a premier look

Combining electroforming with base molds made of plastic or aluminum allows for the creation of lightweight yet extremely durable decorative branding. Typically, electroformed nameplates are about 0.0078" to 0.0118" thick, making them suitable for smaller, thinner applications. However, when electroforming is used with plastic or aluminum base molds, you can achieve thicker, more robust product branding without compromising on detail or quality. Frequently utilized in industries like golf, automotive, motorcycle, eyewear and more.

-

1. Cleaning

A crucial step involves thoroughly cleaning the substrate to remove any contaminants, oils, or debris that could interfere with the metal deposition. A clean surface ensures that the conductive and resist layers adhere properly, leading to a more precise and uniform process.

-

2. Coating

The clean substrate is coated with a conductive layer if it's non-conductive or with a light-sensitive photoresist in the case of conductive substrates. For non-conductive materials, a conductive paint or spray containing metallic particles is applied, allowing for the electroforming process to occur on materials like plastic or aluminum.

-

3. Exposing

Substrate coated with photoresist is exposed to ultraviolet light. A mask is used to create the desired pattern on the substrate. Where the light hits the photoresist, it hardens, defining the areas where the metal will not be deposited. This step is critical for transferring the intricate designs onto the base material.

-

4. Developing

Next the substrate undergoes a developing process where the unexposed photoresist is washed away, revealing the pattern that will form your badge's design. This step refines the design, preparing it for the metal deposition phase.

-

5. Electrodeposition

This is where the actual metal deposition occurs. The substrate is submerged in an electrolytic bath, and a current is applied, causing metal ions from the solution to adhere to the exposed conductive areas. Over time, these ions build up to form a solid metal layer.

-

6. Harvesting

The final step is harvesting, where the metal part is removed from the substrate. If the substrate is a permanent part of the product, it remains; if not, it's dissolved or mechanically separated, leaving behind the decorative piece.

Frequently Asked Questions

What is electroforming?

Electroforming is a precise metal forming process that fabricates thin metal parts through the deposition of metal onto a patterned substrate. This advanced manufacturing technique is renowned for its ability to produce parts with complex shapes and ultra-fine details, which are often challenging to achieve with conventional methods.

Benefits Over Other Manufacturing Processes

Electroforming stands out for its high precision, ability to create complex geometries, and excellent surface finish. Unlike machining or casting, it's an additive process, reducing material waste and enabling the production of lightweight parts. It also allows for greater design flexibility, enabling us to create intricate and unique parts that would be difficult or impossible to produce using traditional methods.

How is electroforming different from 3D printing?

These are distinct manufacturing processes, each with its unique methodologies and advantages:

- Manufacturing Process: Electroforming is an additive manufacturing process that involves metal deposition onto a mandrel or substrate, which is later removed, leaving behind a thin metal part. In contrast, 3D printing, builds objects layer by layer from a digital model, typically using materials like polymers, resins, or metals.

- Materials Used: Electroforming primarily uses metals such as nickel or copper. 3D printing offers a broader range of materials, including plastics, resins, metals, and composites, depending on the printer's technology.

- Detail and Accuracy: Electroforming is known for its high precision and ability to produce very detailed and complex metal structures, which is particularly beneficial for applications requiring fine features and tight tolerances. While 3D printing can also achieve high detail, the level of precision and surface finish can vary significantly based on the technology (e.g., FDM vs. SLA vs. SLS).

- Surface Finish: Electroformed parts typically have a very smooth and premier surface finish, which might require minimal post-processing. On the other hand, 3D-printed parts often show layer lines and may require additional finishing processes to achieve a smooth surface.

- Strength and Durability: Electroformed components can be extremely durable and strong, especially when made from metals like nickel. 3D-printed parts' strength and durability can vary widely based on the printing material and technology, with some methods producing parts that can be nearly as strong as traditionally manufactured components.

- Design Flexibility: Both processes offer high design flexibility, allowing for the creation of complex and intricate shapes that would be challenging or impossible to achieve with traditional manufacturing methods. However, each has its own design constraints based on the nature of the process and the materials used.

- Production Speed and Volume: 3D printing is often faster for producing small quantities of parts since it doesn't require a mandrel or mold.

How precise is electroforming?

Ability to achieve exceptional precision, down to 1-2 microns, enabling the production of highly detailed and accurate metal parts.

How is electroplating different?

While both processes involve metal deposition, electroforming creates standalone metal parts by building up metal layers on a mandrel, which is later removed. In contrast, electroplating adds a thin metal layer onto an existing object to enhance its surface properties.

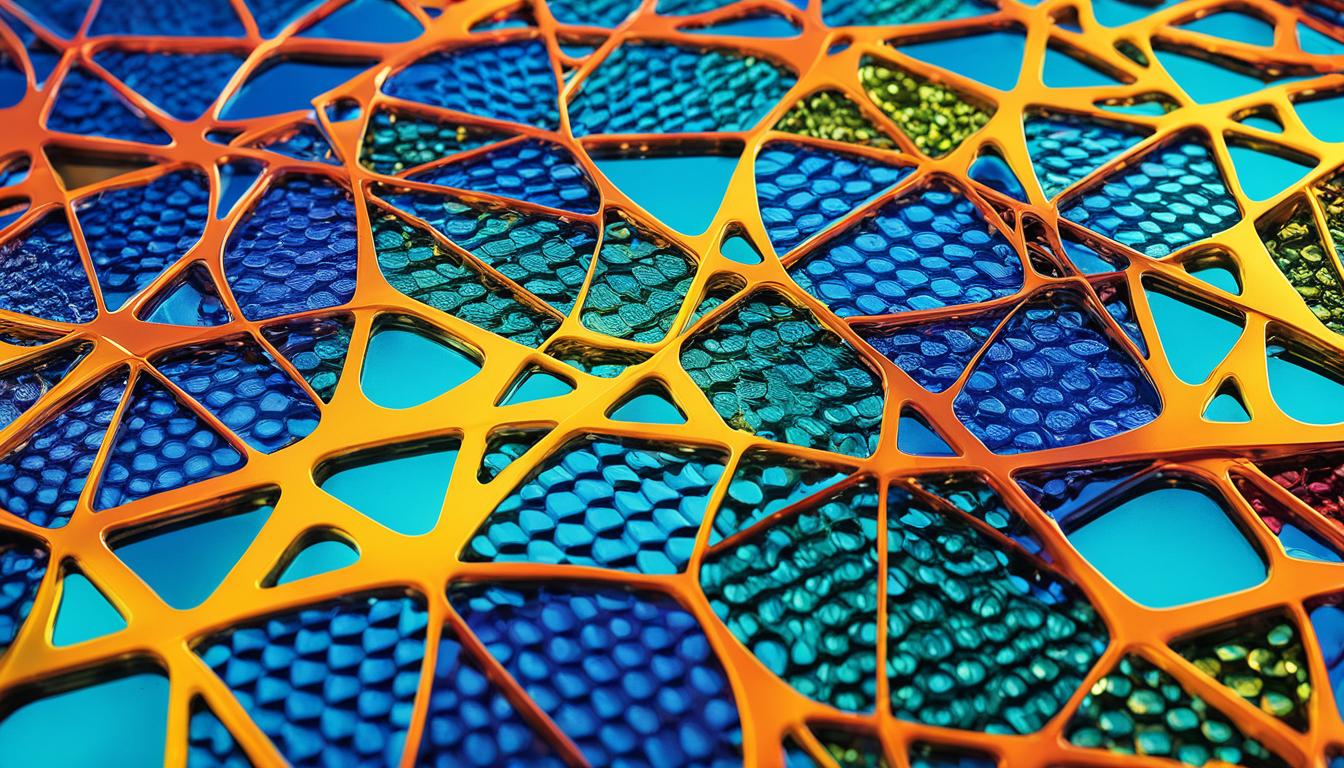

Can electroformed mesh be incorporated into our nameplate design?

Our electroformed mesh is a unique blend of precision and artistry, by meeting at the crossroads of aesthetic and functionality. Its versatility makes it a favorite among brands across diverse industries, from cosmetic to industrial applications. Mesh is typically crafted from thin, perfectly uniform metal layers. Its surface is defined by intricate, symmetrical patterns—whether fine and delicate or bold and geometric—that catch and play with light, creating a striking visual effect on your products. The mesh is incredibly lightweight yet remarkably strong, with edges so clean they seem almost sculpted. Its metallic finish, available in a range of options from polished chrome to brushed nickel, radiates luxury.

We can also create perforated branding and decorative trim using stainless steel and etching through the metal. The method we use will be dependent on the application and desired appearance.

- Use electroform or chemical etching to create air perforation.

- Very intricate patterns can be created using different sizes and shapes.