Understanding Custom Badging Pricing

There are many factors that determine the pricing for your custom badges and other product branding items. By understanding these factors, we can work with you to find the best solutions that meets your needs and desires. Here are a few influencing factors:

- Quantity

- Material

- Dimensions

- Manufacturing Process

- Surface Process

- Colors Required

- Type of Fitting

- Thickness

- More!

Understand how these influence the price of your badges may help you when deciding the best choice for your needs.

1. Quantity

You’re probably aware of the concept, “larger orders lead to lower costs per unit,” and that’s true at Trailblazer as well. The reason behind this is that a substantial part of the expense is tied to the initial setup of equipment and molding, so once production is in full swing, producing more items brings down the cost per unit. In addition, when repeat orders are necessary, as is common in the industrial sector, future orders can be processed quicker and cheaper as mold costs is no longer a factor.

2. Materials

The choice of materials suitable for your custom badges is dependent on numerous factors, such as the environmental conditions it will face (considering temperature, humidity surface energy, elements), the type of surface it will adhere to (whether smooth, textured or curved), and various other considerations. We have access to the most competitive pricing on a wide range of materials.

More Expensive: Stainless Steel, Brass, Gold, Silver.

More Economical: Acrylic, Aluminum, Polyester, Polycarbonate, Vinyl.

3. Dimensions

Larger sizes don’t always equate to higher costs, but typically, the more material required for your product, the more the price may increase. What exactly are dimensions? The overall height and width for your custom badges or other branding, trim.

- Thickness also plays an important role in costs. If you're not sure about the ideal thickness for your application our engineers can help provide you recommendations.

4. Manufacturing Process

The manufacturing technique you select will directly affect pricing, as techniques like electroforming or die casting often involve more specialized processes and equipment, leading to higher costs. However there is more to it than that...

Example:

- At smaller quantities, metal stamping may be cheaper than injection molding, but for very large volumes, injection molding may be cheaper per unit and more efficient. Each case is unique.

- Nameplates with very large dimensions are more cost effectively produced using domed polycarbonate than using say electroforming.

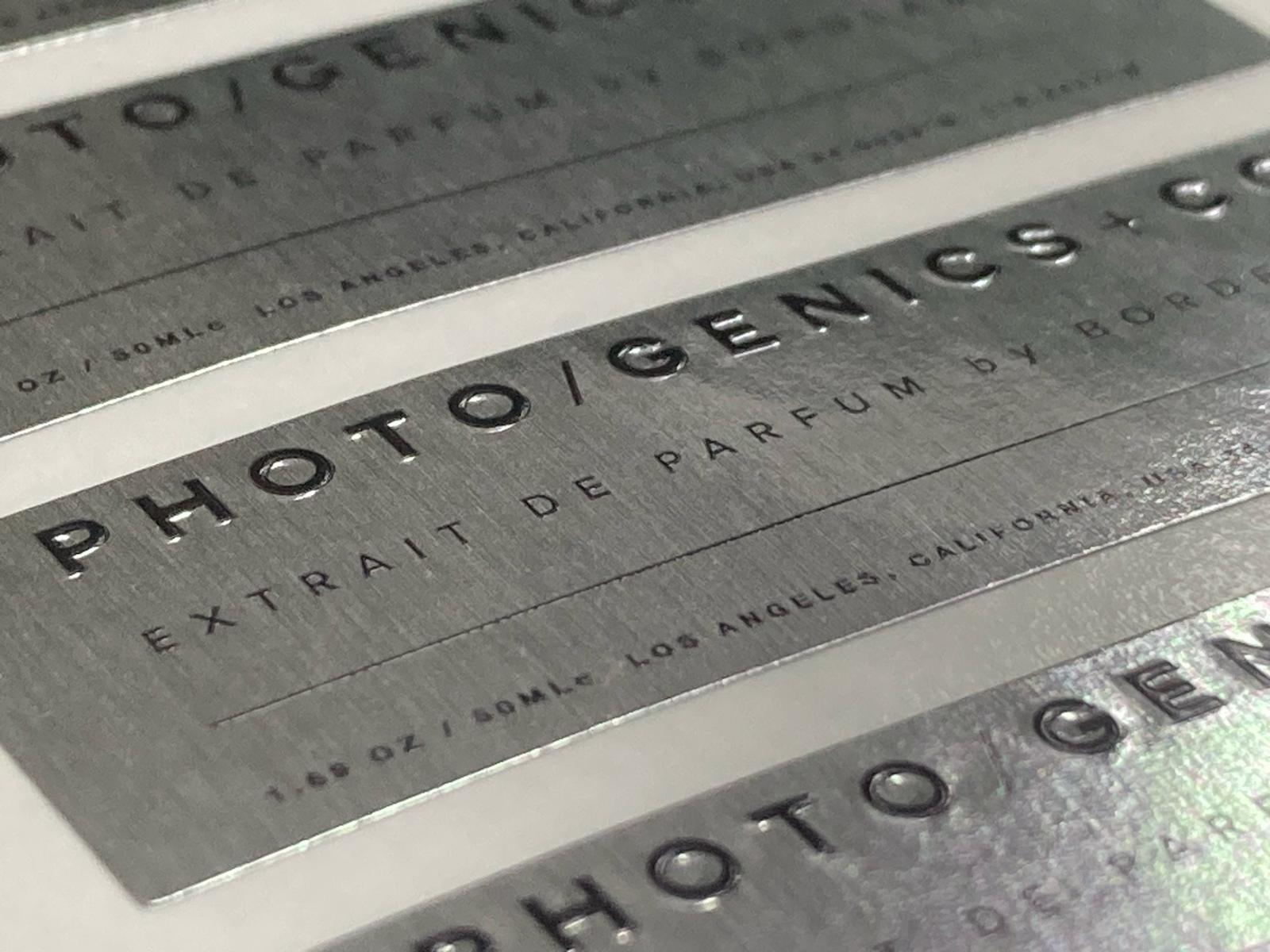

5. Surface Process

The cost of custom bading and other products will also be influenced by the surface process(es) you opt for, with different techniques that will usually increase in pricing due to their complexity.

Examples:

- Badges that require multi-level embossing with paint will be more expensive than those with a flat surface and digital printing.

- Nameplates with a chemically etched design, diamond cutting and color filling will be more expensive than those manufactured using a flat screen printed surface with sandblasting.

6. Type Of Attachment

The attachment method you choose will also affect the overall cost, as there are different types of adhesives, mounting holes or tabs.

Example:

- The type of adhesive utilized for applying decorative trim to the exterior of a vehicle will be different from the type of adhesive used on a nameplate going on equipment that will be indoors in normal temperatures.

- A label exposed to harsh chemicals will require a different adhesive from a tag being applied to furniture that will be indoors.

7. Number Of Colors

Typically, designs featuring multiple colors tend to be more expensive than those with just a single color. This is especially the case when screen printing or when a color gradient is required.

8. Type Of Protective Coating

The type of protective coating required can influence the overall cost, with thickness of coating generally adding to the expense due to the enhanced durability and protection. Types of coating: UV, Varnish and Polyurethane Resin.

Example:

- OEM car manufacturers have stringent requirements for their car badges. For example, most car manufacturers will require their car badges to pass 500 hours of the Neutral Salt Spray (NSS) test. This means their badges will require a thicker layer of coating than an organization who may only require 120 hours.