Product Details

Materials

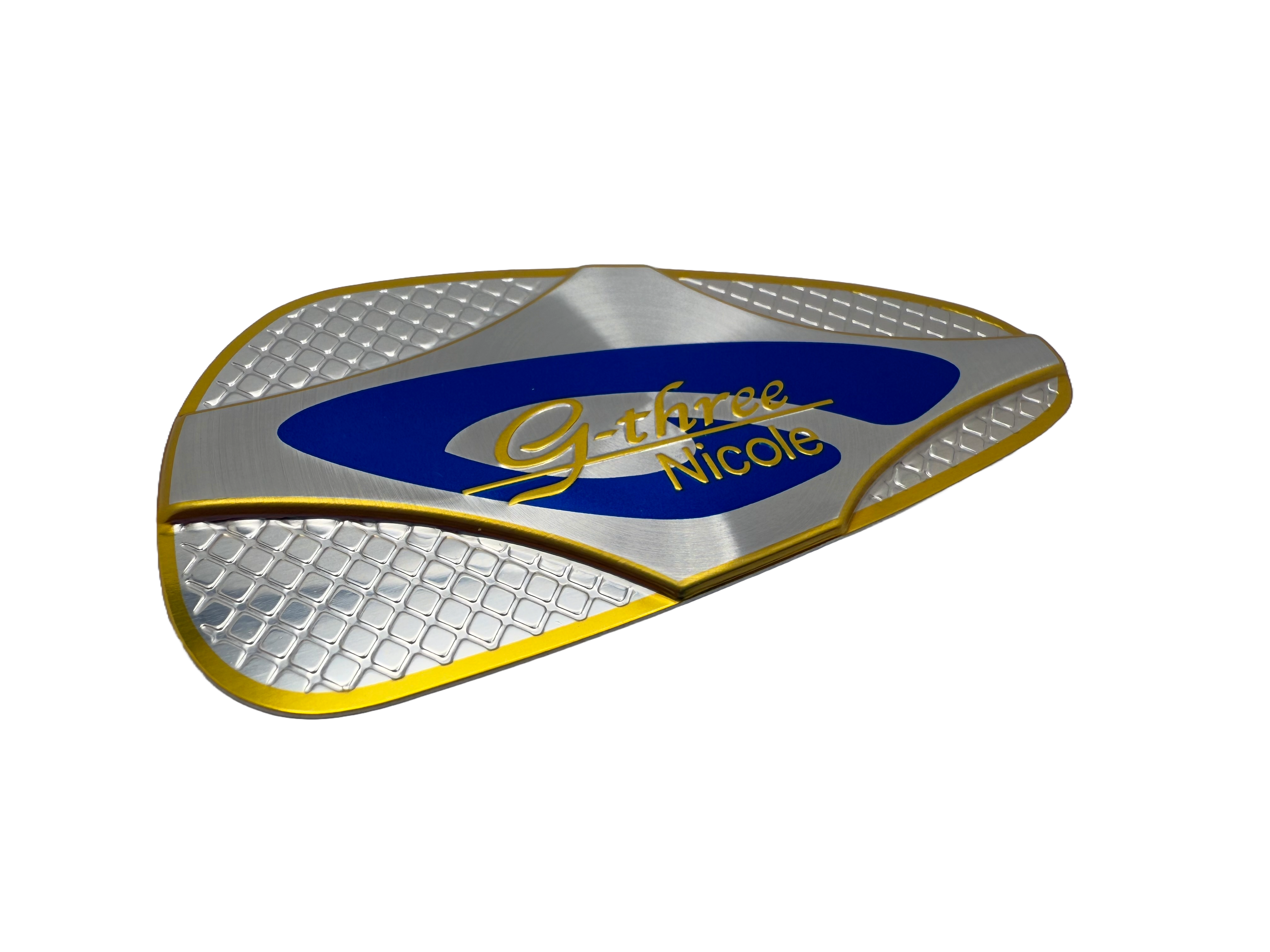

Materials that can be utilize for golf badging include:

- Aluminum

- Anodized Aluminum

- Stainless Steel

- Nickel (Electroforming)

- Carbon Fiber

- Plastics

- Material Combinations

Manufacturing Process

We utilize the following fabrication processes:

- Metal Forging

- Metal Forming

- Metal Stamping/Embossing

- Electroforming

- Coining

- CNC Machining

- Injection Molding

- In-Mold Decoration

Surface Processes

Commonly utilized surface processes for the golf industry:

- Anodizing

- Painting - Spray Painting & Injection

- Metallic Painting

- Polishing

- Screen Printing, Digital Printing & Offset Printing

- Chrome Plating - Nickel Plating - Gold Plating

- Physical Vapor Deposition (PVD)

- Diamond Cutting

- Bead Blasting

- Sandblasting

- Doming - Domed Badges

- Enameling

- Engraving

- Hot Stamping

- Pad Printing

- Etching (Chemical & Laser)

- More!

Finishes

Below are common finishes we offer:

- Brush

- Stripe

- Spin

- Complex

- Circles

- Squares

- Stripes

- Woodgrain

- Patina

- Leather

- Stone

- Patina

- Marble

- Texture

- Linear

- Random

- More

Attachment

Attachment methods include the following:

- Adhesives

- Mounting Holes

- Tabs

- Fastners

- More

Artwork/Engineering Drawings

Commonly known as vector or source files. In short, vector files allow us to turn your golf club medallion design concepts into tangible products.

If you do not have artwork, don't worry. Our designers can help convert your design into production ready drawings. It is best if you can provide us with pictures, sketches and all other information of your design. We do the rest, free of charge to you.

Designing a emblem from scratch does incur a fee and will be dependent on various factors.

No Risk, All Reward Guarantee

How to buy

Trusted By Icons, Made For The Bold

Shine Bright Like A Diamond With Jewelry Like Badging

In the golfing industry, jewel-like finishes on equipment such as putters, wedges, irons, woods, hybrids, and golf bags showcases your brand's artisanal craftsmanship and precision, creating iconic branding that golfing enthustist crave with an insatiable appetite. Our rapid prototyping capabilities enable us to swiftly produce custom golf trim, accents, functional components and badging in various materials, finishes, and attachment methods, ensuring each piece aligns with your brand. This approach allows for efficient iteration and refinement, resulting in distinctive products that stand the test of time.

Detail Driven Branding For Premium Golf Products

-

Learn More

Learn MoreWedges

-

Learn More

Learn MorePutters

-

Learn More

Learn MoreIrons

-

Learn More

Learn MoreWoods

-

Learn More

Learn MoreHybrids

-

Learn More

Learn MoreGolf Bags

Frequently Asked Questions

Are you able to produce golf bag badges?

Yes, we design and produce emblems, labels and nameplates for golf bags.

What are the setup or tooling fees associated with production?

A one-time setup or tooling fee will apply to most initial orders to create molds or dies for your specific design. The fees can vary wildly depending on your design, complexity, material and manufacturing process. Tooling fee is only paid on the initial order and does not need to be paid on subsequent orders of the same badge.

How do we ensure color accuracy across our product lines?

We primarily utilize Pantone Matching System (PMS) colors, but use other methods as well, such as CMYK values and requesting samples of existing branding.

What types of durability testing do you offer?

Below are the tests we offer in-house. 3rd party testing is available upon request.

- Heat

- Dimensional Layouts

- Copper Accelerated Acetic Salt Spray

- QUV

- Salt Spray

- Adhesion

- Thermal Cycles

- Film Thickness

- RCA Abrasion

- Pencil Hardness

- Visual Color Evaluation

- Stain/Chemical Resistance

- More!

How do we handle design revisions during the production process?

Establish clear communication channels with you to accommodate design changes and help give you a better understanding of how revisions may impact timelines and costs.