DuraDome™ Domed Badges Built for Durability and Visual Impact

Built From The Dome Out

You are not buying a sticker. You are buying a protective lens built into your badge. Our resin domed badges, domed labels, and domed tags are custom manufactured for real world use where wear, weather, and handling are unavoidable.

What Are Domed Badges, Labels & Tags?

A domed badge is defined by its clear, raised surface. The polyurethane dome becomes the outer layer of the badge, creating visible depth and a sealed barrier that protects everything beneath it. Unlike flat badges, labels, or nameplates, the dome itself performs the work, shielding graphics and data from wear while amplifying visual impact. Domed badges, labels, and tags are selected when logos or critical information must sit beneath a protective lens rather than on an exposed surface.

Types Of Domed Badges

Below are the domed badge material paths we offer, built for different surfaces and performance needs.

Metal Domed Badges

Chosen for permanent premium brand presence

- Optional embossing adds premium depth

- Trusted choice for OEM automotive branding

- Superior resistance to heat, weather and chemicals

Plastic Domed Badges

Chosen for lightweight, bold branded impact

- Lightweight construction reduces overall weight

- Flexes to fit curved products

- Scalable branding with lower tooling

How to Order Custom Domed Badges

Choose Your Design

Send Your Artwork

Review & Approve

Receive Your Order

How Domed Badges Are Made

Each domed label begins with a precision printed or decorated base material such as aluminum, polyester, polycarbonate, or vinyl. Once the artwork is applied, a carefully controlled layer of clear polyurethane resin is dispensed over the surface. As the resin cures, it naturally flows to the edges of the design, forming a smooth raised dome that permanently bonds to the substrate. The finished result is a flexible, durable, and visually striking domed tag built for real world use.

Why Domed Badges, Labels, and Tags Make Sense

Depth and Visual Presence

The raised dome adds dimensionality and gloss that immediately elevates brand perception.

Built In Protection

The dome becomes the surface, shielding graphics from scratches, wiping, handling, and daily contact.

Long-Term Readability

Fine print, serial data, and QR codes stay legible because the printed layer is sealed beneath the dome.

Outdoor & Cleaning Resistance

Domed products are commonly used where sunlight, moisture, and cleaning are expected because the dome protects the graphics beneath.

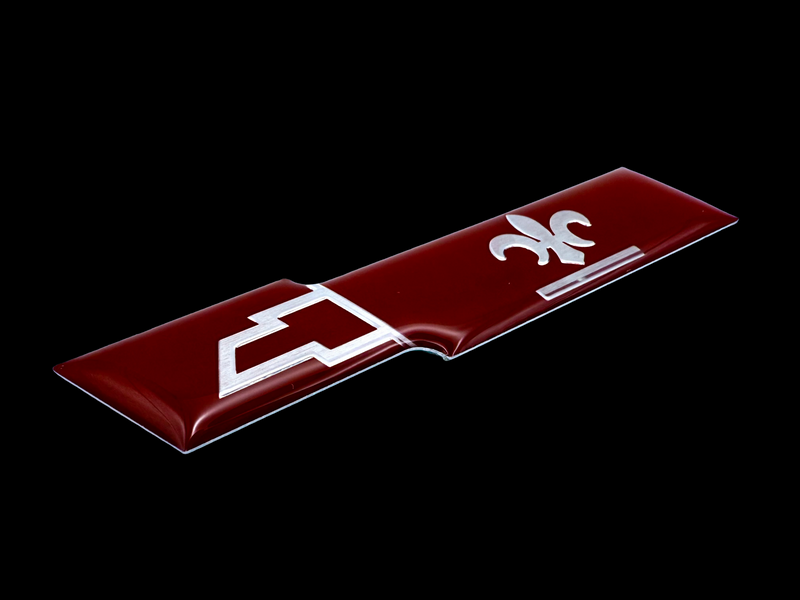

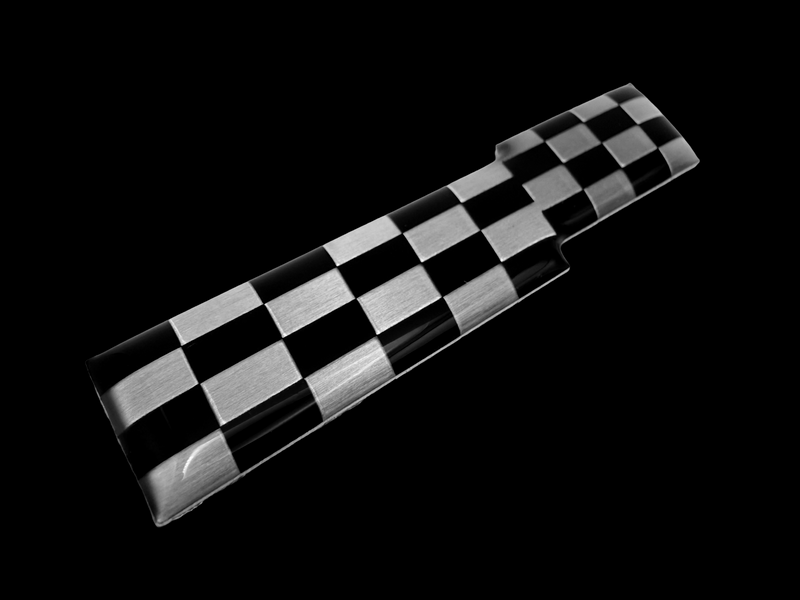

Custom Domed Badge, Label & Tag Gallery

Common Uses For Domed Badges

Discover how industries worldwide rely on our precision-crafted resin domed labels to elevate their products with stunning 3D depth, exceptional durability, and a premium finish that commands attention.

Automotive Branding

Wheel center caps and steering wheel emblems for premium vehicle branding that withstands extreme temperatures and UV exposure.

Product Authentication

Electronics and luxury goods featuring embedded QR codes for product verification, warranty registration, and anti-counterfeiting protection.

Sports Equipment Identity

Bicycle frames and golf clubs with permanent brand identification that resists scratches, weather, and heavy use during athletic activities.

Recognition & Awards

Corporate plaques and achievement trophies with raised, glossy logos that add prestige and perceived value to employee recognition programs.

Promotional Marketing

Custom keychains and phone accessories for trade shows and corporate gifts, creating memorable brand impressions that recipients keep and use daily.

Equipment Identification

Industrial machinery and control panels with durable asset tags, serial numbers, and safety information that remain legible in harsh manufacturing environments.

Retail Display Enhancement

Point-of-purchase displays and product packaging with eye-catching 3D logos that increase shelf appeal and drive consumer purchasing decisions.

Premium Product Finishing

Appliances and furniture with luxury brand emblems that communicate quality craftsmanship and justify premium pricing through superior aesthetics.

Polyurethane vs Epoxy Comparison

See why polyurethane is the superior choice for long-lasting branded badges.

| Feature | Polyurethane | Epoxy |

|---|---|---|

|

UV Resistance

|

||

|

Chemical Resistance

|

||

|

Heat Resistance

|

||

|

Flexibility

|

||

|

Self-Healing Properties

|

||

|

Longevity

|

||

|

No Yellowing/Fading

|

||

|

Outdoor Environment Suitability

|

Resin Dome Badges FAQs

How can you tell the difference between polyurethane and epoxy?

You can tell the difference between polyurethane and epoxy by their appearance, feel, and how they react over time. Here are the main ways to tell them apart:

- Polyurethane usually is flexible and soft to the touch (can be rigid), while epoxy is hard and rigid.

- Polyurethane stays clear and glossy for years, but epoxy tends to yellow over time

- Polyurethane resists cracking, shrinking, and peeling, while epoxy can become brittle in sunlight or heat

- Polyurethane bends slightly and returns to shape, making it better for curved or outdoor surfaces

- Epoxy burns and turns black when heated, while polyurethane liquefies but does not hold a flame

- Polyurethane is the better choice for long-term, outdoor, and high-quality applications

What industries as domed emblems used in?

They’re used in automotive, marine, electronics, industrial, cosmetic and consumer products to display logos, model names, or brand emblems. They’re also popular for promotional items and product identification tags.

What are the lead times?

3-4 weeks from the time we receive artwork approval.

What are common mistakes when ordering domed labels?

Using tiny text, sharp corners, or low resolution logos are the most common. Poor surface preparation or using the wrong adhesive for the substrate can also lead to edge lifting or poor adhesion.

How thick are domed badges?

Use collapsible tabs for more detailed information that will help customers make a purchasing decision.

Ex: Shipping and return policies, size guides, and other common questions.