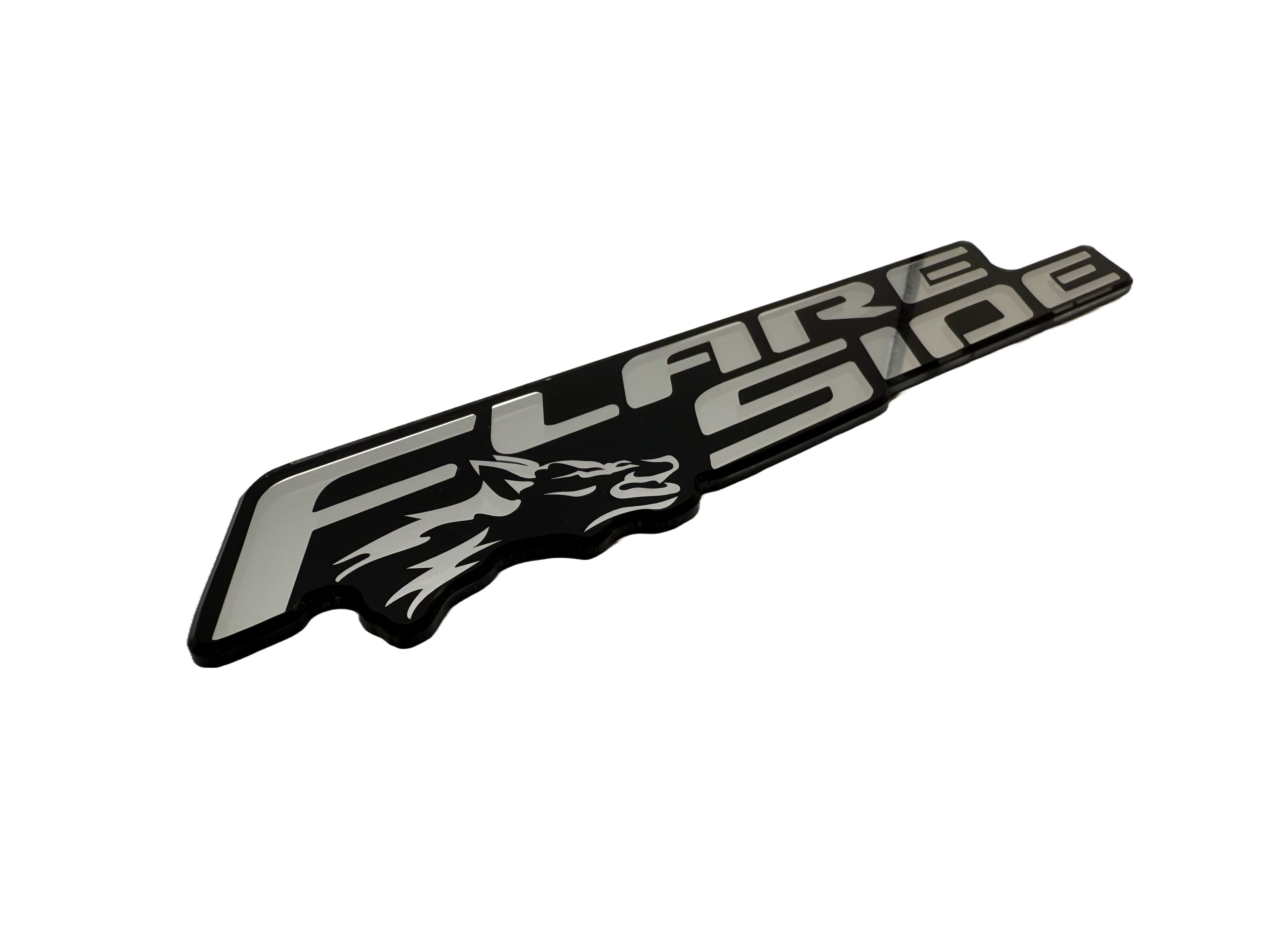

Product Details

Materials

Materials that we utilize include:

- Acrylonitrile butadiene styrene (ABS)

- Polycarbonate (PC)

- Polyester (PET)

- Acrylic - Transparent Acrylic

- Vinyl (Decals)

- Silicone

- Rubber

Manufacturing Process

We utilize the following techniques to produce plastic branding:

- Injection Molding

- Laser Cutting

- Doming

Surface Processes

Commonly utilized surface processes:

- Painting - Injected Paint or Spray Painting

- Screen Printing, Digital Printing & Offset Printing

- Chrome Plating - Nickel Plating - Gold Plating - Black Chrome Plating

- Physical Vapor Deposition (PVD)

- In-Mold Decoration (IMD)

- In-Mold Labeling (IML)

- Anodizing

- Diamond Cut

- Hairline Finish

- Sandblasting

- Doming - Domed Badges

- Enameling

- Engraving

- Hot Stamping

- Pad Printing

- Gloss

- Brushed

- Mill

- More!

Attachment

Attachment methods include the following:

- Mounting Holes

- Adhesives

- Mounting Holes

- Fastners

- Tacks

- Tabs - Can be part of the mold or welded on. Certain limitations apply.

Artwork/Engineering Drawings

Commonly known as vector or source files. In short, vector files allow us to turn your raised emblem design concepts into tangible products.

If you do not have artwork, don't worry. Our designers can help convert your design into production ready drawings. It is best if you can provide us with pictures, sketches and all other information of your design. We do the rest, free of charge to you.

Designing a badge from scratch does incur a fee and will be dependent on various factors.

No Risk, All Reward Guarantee

How to buy

Echoes of Vision in Letter Logos

Elevate your brand's presence with custom plastic molded letters, scripts and logo letters, designed to engage and astonish all who encounter your product.. Choose from a variety of finishes, including chrome-plated and full-color options, crafted from premier materials like 3-D polyester and ABS. We offer cost-effective solutions for small and large runs. Let your letter signage tell a compelling story that captivates and connects.

Ascend To Greatness Alongside Some of The Best

Innovative Engineering to Help Elevate Within Your Market

-

Learn More

Learn MoreAutomotive

-

Learn More

Learn MoreFurniture

-

Learn More

Learn MoreIndustrial

-

Learn More

Learn MoreCosmetic

-

Learn More

Learn MoreSporting Goods

-

Learn More

Learn MoreElectronics

Frequently Asked Questions

What are the differences between acrylic and molded letters?

Acrylic letters are typically laser-cut, resulting in sharp, precise edges and a solid structure. In contrast, plastic letters are often formed using molds, giving them rounded edges and a hollow back. Both types are durable; the choice depends on the desired aesthetic and application.

Can plastic letters be used for interior applications?

Yes, plastic branding is suitable for both interior and exterior applications. Their versatility allows them to be used in various settings, including on cosmetics exposed to harsh chemicals, automobiles exposed to variety of weather conditions and more.

Are any plastics environmentally friendly?

In general, plastic is not as eco-friendly as metal. Materials such as acrylic & polycarbonate are considered eco-friendly to a certain extent as they can be recycled and re-used. If being enviormentally friendly is your goal then we suggest using a metal such as aluminum.

Can plastic emblems be illuminated?

Yes, custom emblems can be designed to accommodate various lighting options, including LED modules, to create illuminated signage to enhance visibility and aesthetic appeal. Illuminated badges have increase in popularity over the last few years, being commonly used by OEMs for their branding.