Types Of Domed Badges

-

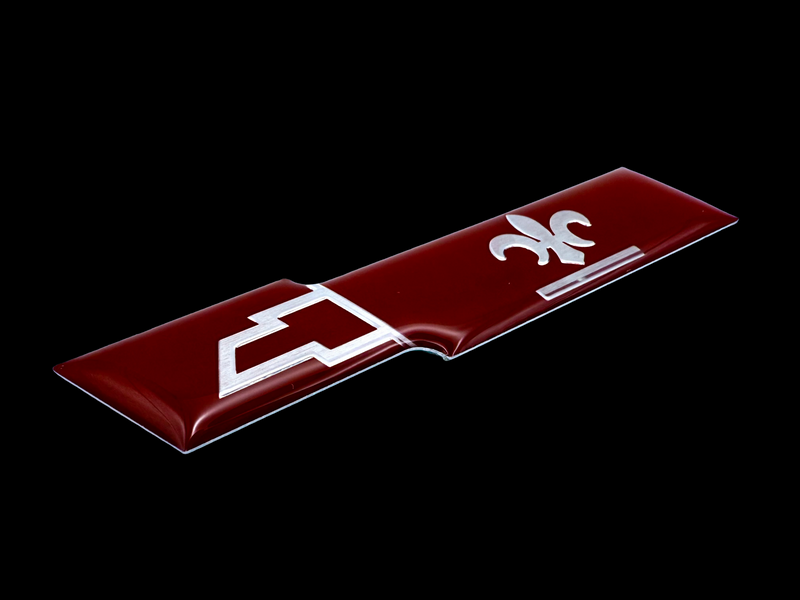

Metal Domed Badges

Quick QuoteMetal doming creates a striking 3D look impossible with plastics, combining unmatched depth and lasting durability that make your products command attention.

-

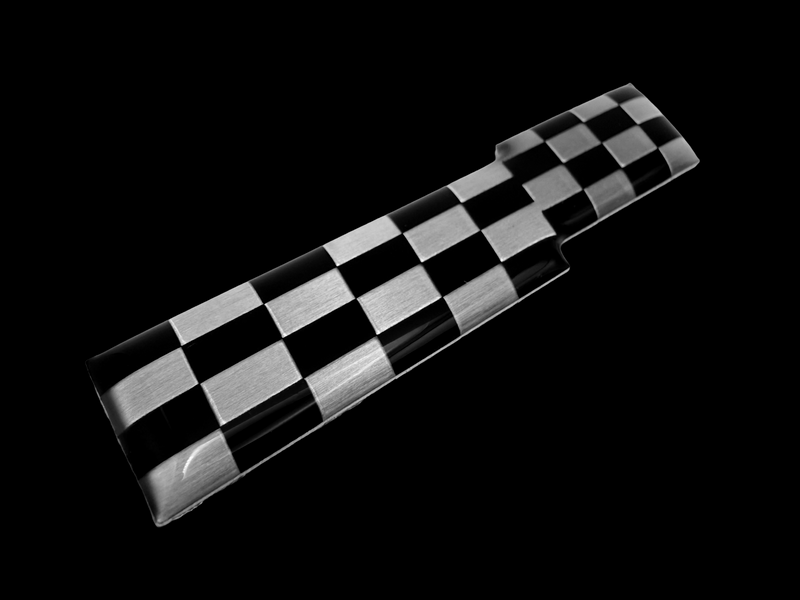

Plastic Domed Badges

Quick QuoteDurable PC and PET plastic badges that can conform to curved surfaces and can be embossed, chrome-finished, or vividly printed. Delivering bold, eye-catching branding that lasts.

-

Quick Quote

Quick QuoteAcrylic Doming

Surface Processes For Domed Emblems

-

Embossing

Available on both plastic and metal, embossing gives form and a 3D effect to your design, most pronounced in metal for a look that feels substantial and built to last.

-

Chrome Plating

Chrome plating can be applied to the background, graphics, or select areas of the surface, creating a striking, mirror-like finish highlighting every contour with depth.

-

Printing

Each domed tag is printed using the process that best amplifies your design. Bold, rich color and sharp detail sealed beneath a crystal-clear, touchable surface that radiates luxury.

-

Metallic Flake

Metallic flake, also known as pearlescent, infuses the badge with fine reflective particles that shift and shimmer under light—giving your design a dynamic, premier look.

-

Diamond Cutting

Diamond cutting draws light across aluminum like liquid silver. A costly but rewarding process reserved for aluminum with razor sharp reflections and jewelry like shimmer.

Shape Options For Domed Decals

-

Circular

-

Oval

-

Square

-

Rectangular

-

Custom

Adhesive Options for Domed Badges

-

3M Adhesive

Quick QuoteOur standard adhesive is premium 3M, carefully selected for its proven strength and reliability, with the specific model chosen based on your unique application to ensure optimal bonding and long-term performance.

-

Standard Adhesive

Quick QuoteFor projects with tighter budgets, cost-effective adhesive alternatives are also available, offering reliable hold and durability while still meeting the performance needs of most domed badge applications.

Why Domed Badges May Be Your Best Choice For Branding

Discover the benefits that set resin domed badges apart from the rest.

3D Depth

Jewel-like dome gives your logo 3D depth, making colors richer and details more vivid, captivating consumers.

Self-Healing

Resist scratching, yellowing & impacts with a resilient, self-healing polyurethane that maintains its shine for years.

Extreme Flexibility

Bends effortlessly to curved or contoured surfaces, keeping its smooth shape and dome, showcasing your logo flawlessly.

Premier Perception

Each domed label feels smooth to the touch, catching light with a glass-like finish that makes color and chrome come alive.

Polyurethane Specifications

| Property | Specification |

|---|---|

| Hardness | Can range from very flexible to firm and unbending |

| Finish | Clear, high gloss, glass like surface that enhances color and depth |

| Durability | Scratch resistant, won't crack, peel or yellow |

| Temperature resistance | -40°F to 200°F |

| Waterproof | Yes |

| UV protection | 5+ years outdoor life |

Custom Domed Badge, Label & Tag Gallery

Flat Surface Badges vs Resin Domed Badges

Explore flat and domed badges to find your best fit.

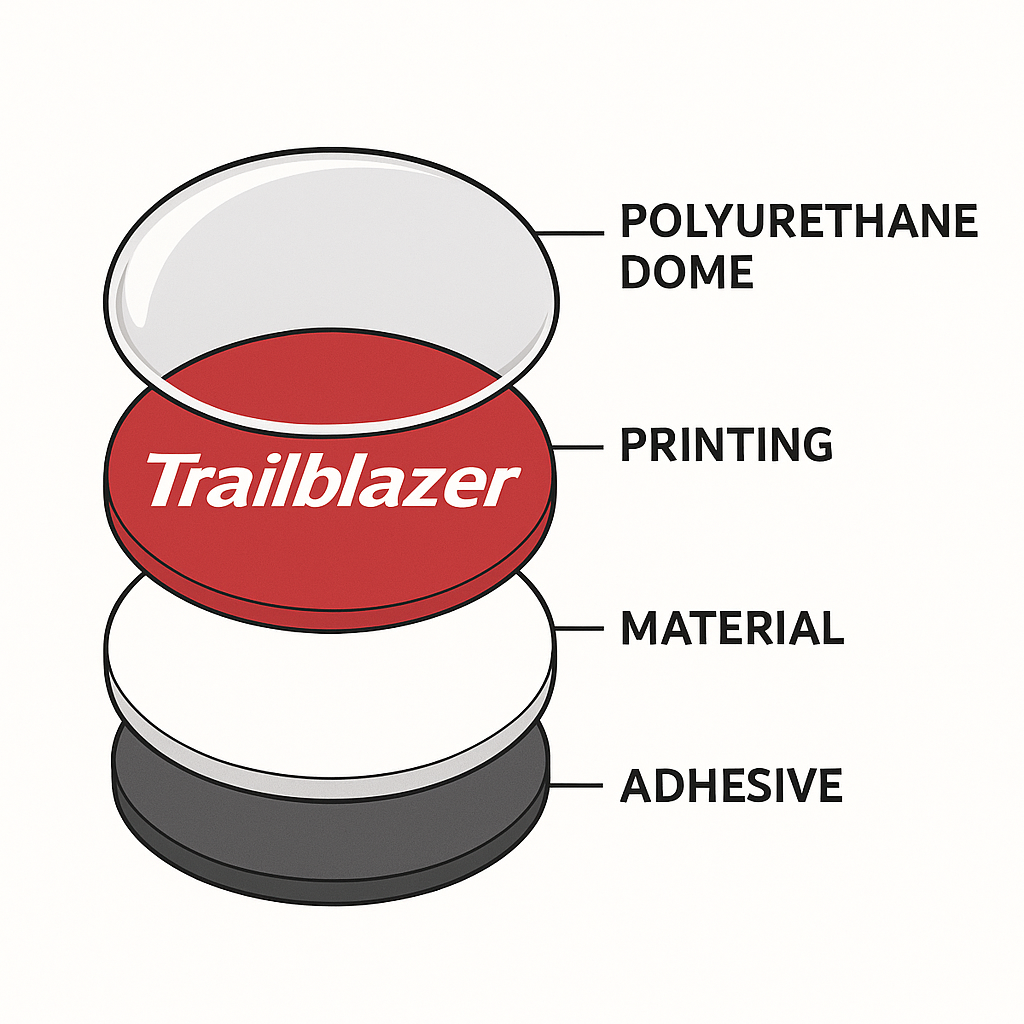

The Layers Of A Domed Emblem

1. Adhesive Layer – Bonds the badge securely to the product surface.

2. Material Layer – Serves as the structural base, typically made of metal or durable plastic.

3. Printing Layer – Displays the custom graphics, colors, and branding design.

4. Polyurethane Dome Layer – Adds a clear, glossy, flexible coating that enhances depth, protection, and 3D appearance.

Polyurethane vs Epoxy Comparison

See why polyurethane is the superior choice for long-lasting branded badges.

| Feature | Polyurethane | Epoxy |

|---|---|---|

|

UV Resistance

|

||

|

Chemical Resistance

|

||

|

Heat Resistance

|

||

|

Flexibility

|

||

|

Self-Healing Properties

|

||

|

Longevity

|

||

|

No Yellowing/Fading

|

||

|

Outdoor Environment Suitability

|

Resin Dome Badges FAQs

How can you tell the difference between polyurethane and epoxy?

You can tell the difference between polyurethane and epoxy by their appearance, feel, and how they react over time. Here are the main ways to tell them apart:

- Polyurethane usually is flexible and soft to the touch (can be rigid), while epoxy is hard and rigid.

- Polyurethane stays clear and glossy for years, but epoxy tends to yellow over time

- Polyurethane resists cracking, shrinking, and peeling, while epoxy can become brittle in sunlight or heat

- Polyurethane bends slightly and returns to shape, making it better for curved or outdoor surfaces

- Epoxy burns and turns black when heated, while polyurethane liquefies but does not hold a flame

- Polyurethane is the better choice for long-term, outdoor, and high-quality applications

What industries as domed emblems used in?

They’re used in automotive, marine, electronics, industrial, cosmetic and consumer products to display logos, model names, or brand emblems. They’re also popular for promotional items and product identification tags.

What are the lead times?

3-4 weeks from the time we receive artwork approval.

What are common mistakes when ordering domed labels?

Using tiny text, sharp corners, or low resolution logos are the most common. Poor surface preparation or using the wrong adhesive for the substrate can also lead to edge lifting or poor adhesion.

How thick are domed badges?

Use collapsible tabs for more detailed information that will help customers make a purchasing decision.

Ex: Shipping and return policies, size guides, and other common questions.