Car Badge Manufacturing

You require custom car badges that not only stand the test of time but also encapsulate the essence of your brand. With a diverse range of materials, finishes, coatings, and attachment options, you can tailor automotive badges precisely to your specifications. You gain the advantage of durability against the elements and flawless adhesion, ensuring your customers associate your brand with quality and longevity. Empowering you to strike the perfect balance between opulence and cost-effectiveness, providing a variety of car badge manufacturing processes that align with your budget without compromising the luxurious look your brand is known for. You’ll find our lightweight badges not only enhance aesthetic appeal but also seamlessly integrate with the latest vehicle technology, assisting you in meeting your innovation and efficiency goals. By partnering with us, you're choosing to equip your vehicles with custom badges that are meticulously crafted to your needs, ensuring each one is a testament to your brand's commitment to excellence and sustainability.

Steering Wheel Badges

As an OEM car manufacturer, your brand's image is paramount, and it's the fine details like the steering wheel badge that leave a lasting impression on your customers. You seek materials that are not only durable and resilient, such as high-quality metals or robust plastics, but also align with the premium look and feel of your vehicles. Advanced materials, including sleek aluminum and electroformed badges, offer a precise, tailored fit to any steering wheel design, ensuring that every driver experiences a touch of luxury and identity unique to your cars brand. By incorporating these materials, you’re not just adding a custom badge—you're enhancing the tactile and visual connection your customers have with your vehicles. You ensure that every time they grip the wheel, they're reminded of the craftsmanship and attention to detail that sets your brand apart. It's not merely about the badge's longevity; it's about reinforcing the emotive bond between your customer and their car, highlighting the sophistication and quality they've invested in. Let’s make every journey your customers take feel exclusive and every turn of the wheel a reaffirmation of their excellent choice.

Wheel Badges

Selecting resilient materials for your wheel badges isn't just about endurance; it's about presenting a lasting image for OEM manufacturers and individual companies alike. The investment in quality badges, like those crafted with robust polyurethane resin domes, translates into a consistent brand presence in the face of environmental stressors—think road salts, UV rays, and the wear of daily drives. For you, this means delivering a product to your customers that maintains its premium look over time, reducing the need for costly replacements and reinforcing your reputation for quality. For the end user, it's the assurance that their vehicle—or fleet—exudes excellence at every turn, enhancing their own brand integrity and, ultimately, driving brand loyalty home.

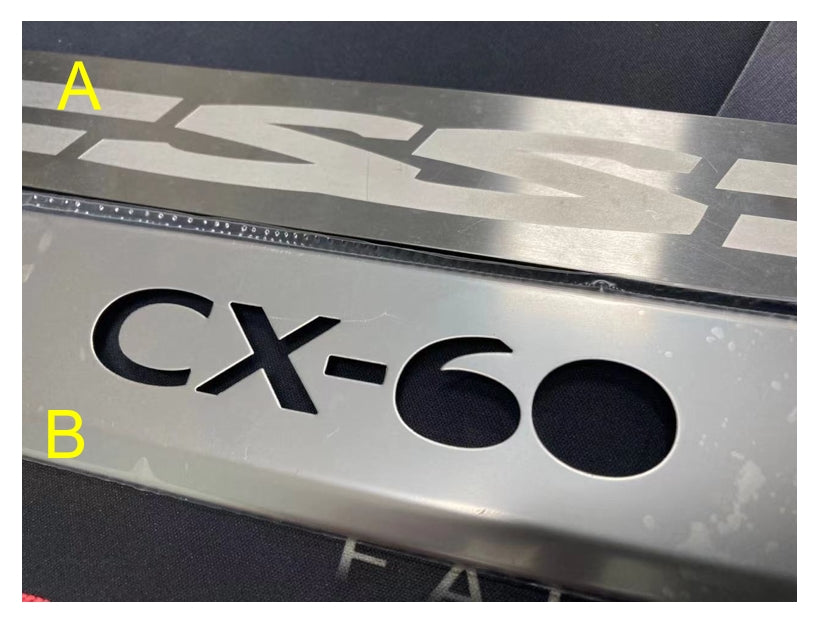

Interior Badges & Nameplates

Interior car badges and nameplates are the quintessence of automotive branding, blending functionality with a premium touch that reinforces a vehicle’s identity from the inside out. Crafted for durability and designed to endure the daily exposure to sunlight and handling, these custom badges are a silent salesman for OEM manufacturers, exuding luxury and attention to detail that resonates with drivers and passengers alike. Whether for luxury vehicles, sports cars, or your everyday ride, selecting high-quality materials for these nameplates can profoundly impact brand loyalty and perceived value, addressing the pain point of maintaining brand prestige in every aspect of the vehicle's design. For businesses and individual clients, this attention to detail ensures that your brand's essence is felt in every interaction, making a lasting impression that stands the test of time.

Metal Sill Plates

Discover the enduring quality and bespoke appeal of metal sill plates, tailored specifically for your automotive models and branding solutions. With custom car accessories designed for longevity and a polished look, you can significantly elevate the customer experience and vehicle value. OEM-specific design solutions ensure that you meet not only the aesthetic expectations but also the practical demands of durability and wear resistance, crucial for maintaining a pristine car interior. These sill plates are an essential element for any OEM car part catalog, providing a subtle yet impactful branding opportunity that resonates with buyers. As a leading supplier for OEM manufacturers, we understand that you need premium materials and precise craftsmanship to address the specific pain points of high traffic wear areas. Let us enhance your lineup's sophistication and customer satisfaction with custom-made metal sill plates, an investment in quality and distinction for your brand.

Engine Cover Badges

Enhance your vehicles' heart with custom engine cover badges that capture your brand's essence and showcase quality craftsmanship directly on the powertrain. You understand the importance of a first impression, and when your customers lift the hood, giving them a badge that reflects engineering excellence and corporate identity can make all the difference. Our badges are crafted from heat-resistant materials, ensuring durability amidst the engine's high temperatures. They're a perfect fit for OEMs who prioritize long-lasting engine aesthetics and want to add a touch of class that customers value. Whether you’re looking to integrate advanced branding or seeking high-performance labeling solutions, engine cover badges are designed to meet the rigorous standards of the automotive industry. You can trust us to deliver a product that withstands the test of time, resonates with your clientele, and elevates your brand's visibility under the hood.

Fender Badges

Set your vehicles apart with premium fender badges, meticulously designed to embody the identity and sophistication of your brand. You recognize the fender as prime real estate for branding—where every passerby's glance is an opportunity to impress. Our customizable fender badges are engineered to endure the elements, boasting weather-resistant qualities that stand up to sun, rain, and road wear. For OEMs who demand visual impact and longevity, these badges serve as a symbol of excellence on every model you produce. They carry the weight of your reputation on their metallic luster, ensuring that the value you promise is the quality you deliver. You'll find these badges are more than an emblem; they're a testament to innovation and a nod to the automotive heritage that discerning customers seek. By choosing our badges, you're not just fitting a vehicle with a label; you're making a statement of superior craftsmanship and unparalleled brand pride.

Hood Ornaments

Car hood ornaments, the iconic emblems proudly perched atop the front of a vehicle, serve as more than just decorative pieces; they are a symbol of your brand's heritage and prestige. As an OEM car manufacturer or a company considering them for branding, you recognize their significance. The choice of material and coating for these custom hood ornaments is paramount—they must endure harsh weather elements like sun, rain, and snow, maintaining their sheen and structural integrity. Opting for robust materials with protective coatings ensures these ornaments stand as enduring testaments to your brand's quality. They address the pain points of wear, corrosion, and fading, common issues that can diminish the perceived value of a vehicle. By investing in high-quality automotive hood ornaments, you're not just adding an aesthetic touch; you're embedding a piece of your brand's identity into each vehicle, enhancing your brand's recognition and the overall allure of your product line. These custom ornaments become a focal point, an element that customers associate with durability and elegance, reflecting the attention to detail and craftsmanship that you, as a brand, stand for.

Manufacturing Processes

-

Metal Stamping

Precision metal stamping stands as a robust manufacturing process, ideal for creating resilient car badges, nameplates, and labels that embody your brand's strength. This process, which meticulously shapes metal sheets using a combination of high pressure and a die, excels in producing uniform, durable, and cost-effective pieces at scale. While etching or electroforming offers finer detail for more complex designs, custom metal stamping is unmatched in its ability to deliver consistent quality and crisp, clean lines, especially with metals like aluminum, brass, and stainless steel. Its suitability shines in projects where structural integrity and volume production are key considerations. For you, choosing metal stamping automotive means choosing a method that mitigates the pain points of variability and wear over time, ensuring that your brand's signature elements are both prominent and enduring. In providing this level of reliability and efficiency, precision stamping adds significant value, signaling to your customers a commitment to quality that's as tangible as the custom badges on their cars.

-

Electroforming

Electroformed badges, nameplates, and labels are the epitome of intricate design and refined elegance in branding elements. Electroforming, distinct from electroplating, is a process that involves depositing metal onto a mold in a precise, controlled manner. This technique is perfect for creating parts with delicate details and complex shapes, which are often challenging with traditional manufacturing methods. Nickel electroforming and copper electroforming, known for their pliability and lustrous finish, are ideal for crafting emblems and logos with a high-quality, sophisticated appearance. For you, our client, opting for electroforming means addressing the need for finely detailed and aesthetically superior branding elements. This method adds immense value by enhancing the overall quality perception of your product, ensuring each component precisely reflects the innovation and craftsmanship behind your vehicle's design.

-

Metal Forging

In the hands of OEM car manufacturers and major businesses, custom metal forging is not just a process—it's a strategic choice for branding and longevity. This revered technique, which includes cold and hot forging, shapes metals like aluminum, brass, and stainless steel into durable, high-precision components. When you, as a discerning client, choose aluminum forging for its excellent strength-to-weight ratio, or brass and stainless steel forging for their corrosion resistance and lasting shine, you're making a statement about the quality of your brand. By opting for metal forging automotive badges, you address not only the manufacturing concerns of material integrity and efficiency but also elevate your brand's perceived value in the market. Whether it's the emblem on a luxury vehicle or the nameplate on high-end equipment, forged metal items resonate with the strength and attention to detail that your clients expect from a leader. This commitment to excellence is the value that sets you apart, ensuring that every product that bears your name is as enduring as the brand it represents.

-

Die Casting

Die casting stands as a premier choice for manufacturing car badges, nameplates, and labels, particularly when you're aiming for volume production with precise detailing. Die casting process involves forcing molten metal—typically non-ferrous alloys like aluminum, zinc, or magnesium—under high pressure into molds, known as dies. The result? High-quality custom die cast badges and die cast nameplates with a level of detail and uniformity that methods like sand casting can't match. It's particularly suitable when you need complex shapes with thin walls and smooth surfaces, often required in automotive branding. Ideal for medium to large production runs, die casting products ensures structural integrity, repeatability, and a superior finish, directly addressing common concerns such as consistency and cost-efficiency in manufacturing. For you, this translates into a streamlined production of emblematic components that exude quality and durability, adding tangible value to your brand's presence in the market.

-

Injection Moulding

Custom injection molding, a cornerstone in badge manufacturing, is indispensable when creating precise and uniform car badges, nameplates, and labels, delivering both volume and detail. This process, which encompasses metal injection molding and plastic injection molding, involves injecting molten material—be it high-strength metals or versatile plastics—into a meticulously crafted mold. It's the method of choice for automotive businesses seeking custom injection molding solutions that merge the strength of metal with the intricate designs that only molding can achieve. Whether you’re creating a prototype injection molding piece or ready for full-scale production, this technique offers unrivaled precision and scalability. It’s ideal for OEMs who require consistent quality across thousands of parts, providing the ability to rapidly produce complex shapes that metal die-casting or machining might not economically allow. ABS plastic injection molding is frequently utilized in the automotive industry. The value it brings to you, the client, is clear: from the sleek emblem on a car grille to the durable label on a dashboard, injection molding ensures your product carries a mark of quality that consumers trust.

-

Lathe Processing

Lathe processing, a fundamental and versatile technique in manufacturing, plays a crucial role in crafting precision components like car badges, nameplates, and labels. This method involves rotating a workpiece on a lathe machine while various cutting tools shape the material to the desired form. Ideal for both metal and plastic materials, lathe processing excels in producing cylindrical and round shapes with exceptional accuracy and smooth finishes. It differs from other methods like injection molding or die casting, as it’s especially suited for creating prototypes or custom designs where intricate detailing and dimensional accuracy are paramount. By utilizing lathe processing, you address the need for bespoke, high-quality automotive components that can be precisely tailored to meet your specific design requirements. This technique offers significant value to you, particularly in the realm of custom car modifications or limited-edition models, where each piece needs to reflect a unique identity and superior craftsmanship.

Surface Processes

-

Chrome Plating

In the dynamic world of automotive detailing, custom chrome plating stands as a symbol of both elegance and endurance, especially for items like chrome plated badges, nameplates, and labels. Chrome plating is a process where a thin layer of chrome is electroplated onto a metal object, providing it with a distinctive, mirror-like finish. This process begins with a thorough cleaning of the base metal, followed by layering of nickel and copper for adhesion and smoothness, before the final chrome layer is applied. Compared to other finishes, chrome plating boasts superior durability, effectively resisting corrosion and wear over time. Its physical characteristics include a bright, reflective surface that adds a touch of luxury to any vehicle. For you, the client, chrome plating solves the pain points of maintaining a pristine and professional appearance for your automotive products in the long run. It brings considerable value to your brand, ensuring that the chrome plated automotive components you choose are not only visually striking but also built to last, enhancing the overall appeal and perceived quality of your vehicles. By incorporating chrome plating in your design, you're opting for a finish that resonates with sophistication and longevity, a choice that mirrors your commitment to high standards.

-

PVD Plating

PVD (Physical Vapor Deposition) plating is not only elevating the standard for automotive finishes on badges, nameplates, and labels but is also setting a new benchmark in environmental responsibility. This innovative process, which involves vaporizing metals like gold and chrome in a vacuum and depositing them onto surfaces, results in a durable PVD coating. It stands out for its resilience and resistance to corrosion and wear, surpassing traditional methods like electroplating. Notably, PVD gold plated and PVD chrome plating offer a lustrous, long-lasting finish without the environmental impact associated with conventional electroplating. This makes PVD an ideal choice for clients looking to balance exceptional quality and aesthetic appeal with environmental consciousness. By choosing PVD plating for your automotive components, you're not only investing in a superior finish that enhances your brand’s image but also aligning with more sustainable manufacturing practices.

-

Copper-Nickel-Chrome (Cu Ni Cr)

Copper-nickel-chrome plating is a premium choice for automotive badges, nameplates, and labels, offering an unmatched blend of durability and elegance. This triple-layer plating process begins with a copper base for superior adhesion, followed by a nickel layer for increased strength and corrosion resistance, and is completed with a chrome finish for a visually striking, mirror-like sheen. Compared to other plating methods, copper-nickel-chrome offers enhanced durability, effectively withstanding environmental factors like UV exposure and moisture, ensuring the longevity of your automotive components. The sleek, polished appearance of copper-nickel-chrome plated badges not only enhances the aesthetic appeal of your vehicles but also addresses common client concerns such as wear and tear, and fading over time. For you, this translates to a value-added investment in your brand's image, assuring customers of the high quality and attention to detail that go into every aspect of your vehicles. By incorporating this advanced plating technique, you're not only elevating the look of your automotive line but also reinforcing a commitment to quality and resilience that resonates with discerning clients.

-

Sandblasting

Sandblasting is a refined yet robust technique increasingly sought after in the automotive industry, particularly for crafting distinct badges with a textured finish. This process involves blasting fine particles at high speeds onto the surface of the badge, effectively etching and roughening it for a unique matte appearance. Sandblasting stands out from other finishing methods due to its ability to create a uniform, non-reflective surface that adds a contemporary, sophisticated look to automotive badges. This technique is ideal for clients seeking an alternative to the traditional glossy finishes, offering a modern aesthetic that still maintains visibility and brand recognition. The durability of sandblasted badges ensures they withstand the daily rigors of automotive use, addressing common concerns of wear and fading. For you, incorporating sandblasted badges means embracing a blend of modernity and durability, enhancing your vehicles' appeal with an innovative touch that differentiates your brand in a competitive market.

-

Chemical Etching

Chemical etching, also known as photochemical etching, is a highly precise and efficient process for crafting automotive badges, etching nameplates, and etching labels. This method, also known as acid etching, involves a careful application of chemicals to create intricate designs on metal surfaces. Chemical etching metal, especially allows for extremely precise metal removal, resulting in sharp, clean lines ideal for detailed automotive components. The versatility of acid etching metal extends to a range of materials, making it suitable for various applications in the automotive sector. This precision metal etching technique is perfect for creating durable and visually appealing badges and nameplates, ensuring they withstand the test of time and maintain their aesthetic appeal. For automotive manufacturers, chemical etching offers a blend of artistic flexibility and industrial robustness, meeting the exacting standards required in the industry. This process not only addresses the need for precision and quality but also offers the versatility to handle complex designs, making it an invaluable tool for automotive branding.

-

Electroforming

Electroforming is an advanced technique highly suited for producing automotive badges, nameplates, and labels with unparalleled precision and detail. This process involves the meticulous deposition of metal onto a conductive pattern, allowing for the creation of thin, yet robust, metallic components. Ideal for intricate designs, electroforming excels in crafting badges and nameplates with complex contours and fine features that traditional methods might not replicate with such accuracy. The electroformed badges, nameplates, and labels are known for their crisp details and smooth finishes, making them a popular choice in the automotive industry for both aesthetic appeal and durability. For manufacturers seeking to elevate their brand's presence on their vehicles, electroformed components offer a solution that combines intricate detailing with structural integrity. This method not only enhances the visual appeal of your products but also ensures they withstand the rigors of automotive use, reflecting a commitment to quality that resonates with discerning customers.

-

Diamond Cutting

Diamond cutting, a highly specialized process, is increasingly being utilized in the automotive industry for creating stunning car badges, nameplates, and labels. This method involves using a precision diamond cutting tool to engrave or embellish metal surfaces, resulting in a finish that is both visually striking and exquisitely detailed. The key advantage of diamond cutting metal is its ability to achieve a high level of precision and clarity in designs, which is essential for intricate logos and text on automotive components. Perfect for adding a touch of luxury and refinement, diamond cutting enhances the overall aesthetic of car badges, making them stand out with their polished, sophisticated appearance. This technique is not just about elevating style; it also ensures durability and resistance to wear, meeting the rigorous standards of the automotive industry. For manufacturers and designers looking to elevate their branding with a distinct, high-quality finish, diamond cutting offers a unique solution that combines artistry with practicality, making every badge, nameplate, and label a testament to excellence.

-

Engraving

Custom engraving is a timeless and precise technique widely adopted in the automotive industry for crafting detailed car badges, nameplates, and labels. This method involves incising designs into metal surfaces, offering a depth and texture that other manufacturing techniques can't replicate. The precision of engraved badges and engraved nameplates is ideal for creating highly detailed and durable automotive branding elements. It allows for a range of styles, from classic to contemporary, making it versatile for various car models. The engraved badges and nameplates stand out for their tactile quality and visual appeal, providing a sense of luxury and attention to detail that resonates with customers. For automotive businesses, engraving offers a unique opportunity to showcase their brand's commitment to quality and craftsmanship. This technique not only enhances the aesthetic appeal of the vehicle but also ensures that the branding elements endure through the life of the car, reflecting an enduring commitment to excellence in automotive design.

-

Printing

The technique of printing on metal and plastic surfaces has become a pivotal aspect in the production of car badges, nameplates, and labels, offering a fusion of versatility and innovation in automotive branding. This method involves applying detailed graphics directly onto the surface of metal or plastic components, providing a cost-effective solution for vibrant and diverse designs. The versatility of this approach allows for a wide range of colors and intricate patterns, making it ideal for custom branding and personalization. Printed badges, printed nameplates and printed labels stand out for their crisp, clear imagery and the ability to capture complex logos and texts with precision. For automotive manufacturers, this means the opportunity to showcase their brand identity with greater creativity and clarity. The value of this technique lies in its ability to meet specific aesthetic requirements while maintaining durability and resistance to environmental factors, ensuring that the badges and labels look as good as new throughout the vehicle's lifespan. Adopting this innovative printing approach can significantly enhance the visual appeal of your vehicles, leaving a lasting impression on customers and setting your brand apart in the competitive automotive market.

Frequently Asked Questions

Do you offer free consultations to help us find the most suitable solutions to our branding needs?

Free Consultations to Perfectly Match Your Branding Needs

Trailblazer understands that selecting the right materials and processes for your branding needs is crucial. That's why we're proud to offer free consultations, guiding you through the myriad of options to find the perfect fit for your specific requirements.

Whether you're exploring the durability of stainless steel for car badges, the elegance of electroformed nameplates, or the versatility of PVD coatings for labels, an team of experts is here to assist. Delving into your brand's vision, target audience, and the intended use of the products to recommend materials and processes that align with your branding strategy.

Consultations cover a range of services, from material selection to process optimization, ensuring that every aspect of your branding aligns with the highest standards. Understanding the importance of creating a lasting impression, and our commitment is to help you achieve this with the most suitable branding solutions.

Take advantage of free consultation service and let us help you make informed decisions that elevate your brand. Contact us today to schedule your session and take the first step towards impeccable branding that resonates with your audience. With our expertise and your vision, the possibilities are limitless.

Do you need us to provide you with a vector file of the car badge, nameplate or label? Can you help us create the file if we are unable to?

When it comes to crafting custom car badges, nameplates, and labels, the process begins with a clear vision and the right tools. One essential element is a vector or AI (Adobe Illustrator) file of the design. This file format is crucial as it allows for resizing and adjusting the design without any loss of quality, ensuring that your branding elements look sharp and professional at any scale.

If you don’t have a vector file ready, there's no need to worry. Our team is equipped to help bring your vision to life. Starting with just a description of your desired look, our skilled designers can create a custom vector file for you. This collaborative process involves your input and feedback, ensuring that the final design aligns perfectly with your brand's identity and vision.

Our commitment to your satisfaction means we are flexible with design alterations. Our designers will work with you, making as many changes as needed until the design resonates with your brand’s message and aesthetic. Whether it's tweaking the font on a nameplate, adjusting the lines on a badge, or refining the overall layout of a label, we are here to ensure every detail is just right.

Embarking on the journey of creating custom car badges, nameplates, and labels with us means you have a dedicated partner in every step of the process. From initial concept to final design, we strive to make the experience seamless and rewarding, resulting in branding elements that you can be proud of.

What is the lead time for custom car badges, nameplates and labels?

When it comes to creating custom car badges, nameplates, and labels, the timeline for production can vary based on several factors, including the choice of materials and the specific manufacturing processes involved. However, we strive to make this process as efficient and transparent as possible for you.

On average, the lead time for producing a sample of your custom design is approximately 14 days from the moment your artwork is approved. This allows us the necessary time to ensure every detail of your design is crafted to perfection. Once you have approved the sample, the production lead time typically ranges from 3 to 4 weeks. This timeframe includes meticulous quality checks to ensure the final product meets our high standards and aligns precisely with your vision.

We understand that sometimes there may be urgent requirements. In such cases, we offer expedited production services. Upon request, we can reduce the lead time to approximately 2 weeks, ensuring you receive your custom products in a timely manner without compromising on quality.

Our commitment is to provide you with not only exceptional custom car badges, nameplates, and labels but also with a service that is tailored to your unique timelines and needs. Whether it's for a special launch, an event, or regular branding needs, we're here to ensure that your products are delivered with the quality and speed you require. Contact us to discuss your specific needs and let us help you bring your branding vision to life.

Do you offer a guarantee on your badges, nameplates and labels?

Trailblazer stands firmly behind the quality of our work, which is why we offer a 100% satisfaction guarantee on all orders. We understand the importance of perfect detailing in automotive branding, and our goal is to ensure that you are completely satisfied with the custom car badges, nameplates, and labels we create for you.

Our guarantee is simple: if you are not entirely satisfied with the final product – whether it's a matter of design, quality, or finish – we will remake it at no additional cost to you. We believe in getting every detail right, and our team is dedicated to working with you until your vision is perfectly realized in the final product.

This commitment to excellence and customer satisfaction is at the core of our business. We understand that your custom car badges, nameplates, and labels are not just branding elements; they are a reflection of your brand's identity and reputation. That's why we take every step to ensure that the products you receive meet and exceed your expectations.

Choose us for your automotive branding needs and experience the peace of mind that comes with our 100% satisfaction guarantee. Let's work together to create outstanding branding elements that truly represent the quality and prestige of your brand.

Why is automobile branding important?

Automotive Branding: Crafting Your Vehicle's Identity

Automobile branding is an integral facet of your brand's narrative, playing a pivotal role in how customers perceive and interact with your vehicles. As a leading branding company, we specialize in transforming every aspect of a vehicle into a testament to your brand’s essence. This extends from the prominent car manufacturers' logos to the finer details of branding elements. Effective auto branding is a strategic blend of aesthetic appeal and brand messaging, crucial for brand development in the competitive automotive industry. It's about creating a cohesive and compelling visual story that resonates with your customers.

Car Badges - The Frontline of Brand Recognition

Car badges are more than mere symbols; they are the visual embodiments of your brand's identity, often positioned at the front grille or rear of the vehicle. These badges are your brand’s signature, instantly recognizable and evocative of the values and prestige your brand represents. As an essential component of automobile branding, car badges serve as a constant reminder of the quality and heritage of your vehicles, making them a vital element in your overall branding strategy.

Nameplates - Detailing Your Vehicle's Identity

Nameplates are crucial in articulating specific information about each vehicle, including model names and edition details. Typically found on the rear or sides of a vehicle, they play a significant role in differentiating various models within your lineup. These etching nameplates go beyond functionality; they are crafted to harmonize with your brand's aesthetic, enhancing the vehicle’s appeal and reinforcing brand recognition.

Labels - Essential Information with Brand Impact

Labels, though smaller in size, are key components in the branding ecosystem of a vehicle. Found within the interior or on engine components, they carry essential information while maintaining brand consistency. These etching labels are designed to blend seamlessly with the overall design, ensuring that every aspect of the vehicle upholds the branding strategy you've carefully crafted.

The Synergy of Branding Elements in Automotive

In the world of vehicle branding, the harmonious synergy of car badges, nameplates, and labels is what sets a brand apart. As brand builders and a reputable branding manufacturer, we focus on each of these elements to develop a cohesive brand design that captures your brand’s ethos and appeals to your target audience. This comprehensive approach to brand development ensures that every aspect of your vehicles, from the prominently displayed logos to the subtly placed labels, works collectively to build a strong, enduring brand identity in the automobile industry.

Are finishes such as engine turn, engine stripe, brush and spin available?

Discover the exceptional range of finishes offered, each uniquely designed to enhance the aesthetic appeal of your products. Catering to diverse design preferences, our finishes – Engine Turn, Engine Stripe, Brush, and Spin Finish – are meticulously crafted to suit your branding needs.

Engine Turn Finish

The Engine Turn finish, renowned for its intricate pattern of fine, overlapping circles or arcs, brings a classic and luxurious touch to metal surfaces. This decorative technique, also known as Jeweling or Guilloché, involves precise engraving to create a captivating, multidimensional effect. Ideal for products where a vintage yet sophisticated look is desired, Engine Turn adds an element of timeless elegance.

Engine Stripe Finish

Our Engine Stripe finish delivers a modern and linear aesthetic with its uniform, straight lines. Achieved through a controlled brushing process, this finish imparts a sleek and contemporary appearance, perfect for products aiming for a refined and minimalist style. Engine Stripe is about precision and understated beauty, making it a popular choice for modern designs.

Brush Finish

Opt for the Brush finish to imbue your products with a subtle, matte look characterized by fine brush marks. This finish, achieved by brushing the metal surface with a fine abrasive, results in a unidirectional satin appearance. It’s particularly suited for products requiring a sophisticated, yet minimalistic touch, offering a unique texture and understated elegance.

Spin Finish

The Spin Finish, or Circular Brush Finish, adds a dynamic texture of concentric circles, creating a visually engaging surface that plays with light. This distinctive pattern, achieved by rotating the piece against a stationary brush, is perfect for products that demand a striking and eye-catching appearance.

Each of these finishes not only enhances the visual appeal of your products but also ensures durability and quality. We invite you to explore how these unique finishes can elevate your brand's identity and resonate with your target audience. Let's transform your vision into reality with finishes that make a statement.

What is badging on a car?

If you're wondering what car badging entails, it's an essential aspect of automotive identity and branding. Let's break down what this means for your vehicle.

Understanding Car Badging

Car badging refers to the emblems, nameplates, labels, and other decorative identifiers attached to a vehicle. These elements display critical information such as the car's make, model, engine type, or special edition status. But it's more than functional; badging is a powerful form of branding and personal expression.

Why Badging Matters

- Brand and Model Identification: Badges help to immediately identify the vehicle's brand and model, an essential aspect in a world where car design is increasingly homogenous.

- Status Symbol: In many cases, a badge indicates a certain level of prestige or performance, such as a badge denoting a high-performance variant of a standard model.

- Personalization: Badging can also be customized, allowing car owners to add a personal touch or show affiliation with a particular group or interest.

Badging Options and Materials

The most common backing for car badges is adhesive, with various options available for strength and durability. 3M adhesives are a popular choice, known for their robustness and longevity, ensuring that badges remain secure under various conditions.

Types of Badging Items

- Emblems and Badges: These can be created through different manufacturing methods like die casting, metal stamping, electroforming, and more, with surface finishes like chrome, etching, diamond cutting, and PVD plating.

- Nameplates and Labels: Offer more detailed information and can be made using similar methods and materials, ensuring consistency in appearance and quality.

The Value of Quality Badging

Quality badging on your car is not just about aesthetics; it's a statement of quality and identity. It enhances the overall look of your vehicle and can impact its perceived value. The choice of badging and its placement can transform your car’s presence on the road.

Whether you’re a car enthusiast looking to customize your ride or just want to understand the importance of your vehicle’s badges, recognizing the role of badging is key. Let’s discuss how we can make your car stand out with the perfect badging.

What are badges on cars called?

Badges on cars are commonly referred to as "car badges" or "automotive badges." These terms encompass various types of branding elements attached to a vehicle, including emblems, nameplates, and logos. They serve to identify the car's make, model, special editions, and can also include trim level designations. These car badges are a key aspect of a vehicle's identity and branding, offering both functional information and aesthetic appeal.