What Are Die Cut Adhesives?

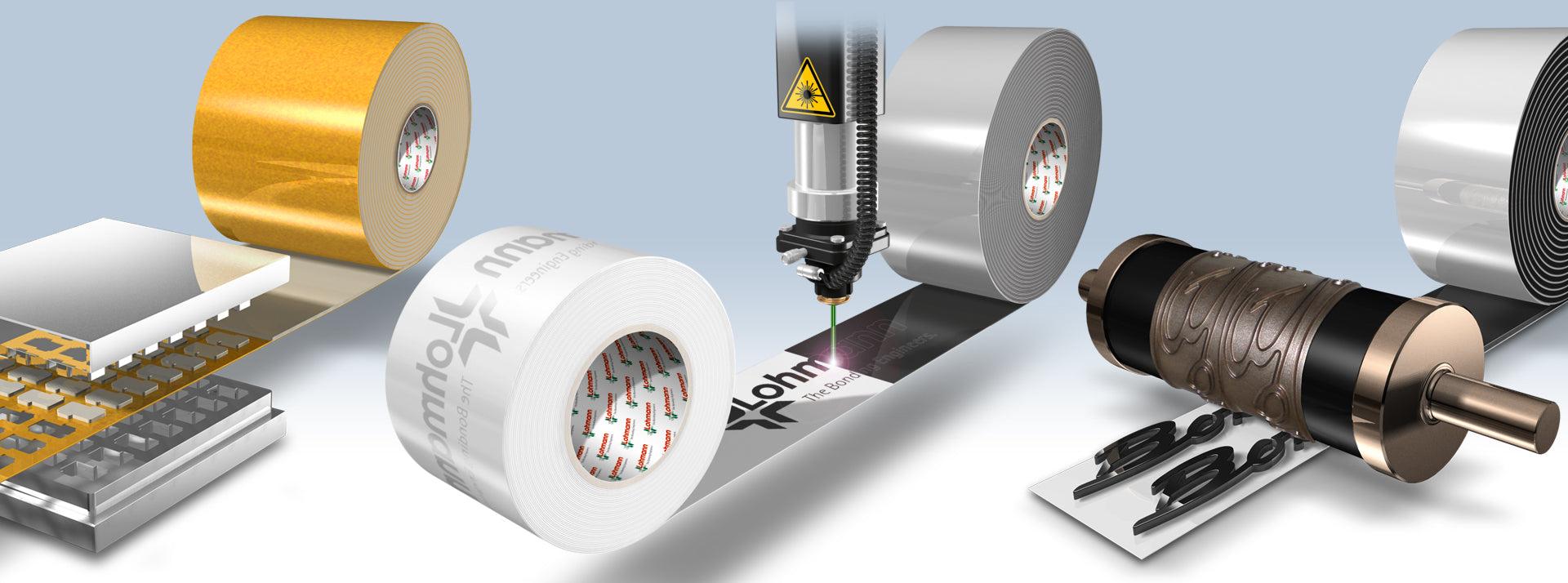

Die-cutting adhesives is a precision-based process where adhesives are cut into specific shapes using a die, tailored to your unique requirements. This method is frequently used across various industries for applications like bonding components, sealing, masking, and providing structural support. By choosing die-cut adhesives, you benefit from a streamlined production process, enhanced product reliability, and a cleaner application compared to traditional methods. Unlike liquid adhesives, which can be messy and require drying time, die-cut adhesives offer immediate and consistent bond strength. Compared to mechanical fasteners like rivets and bolts, they don't compromise the integrity of materials with holes or add extra weight. Die-cut adhesives adapt seamlessly to your design, providing a versatile and aesthetically pleasing solution while enhancing the durability and performance of your products.

-

Acrylic Tape

Learn MoreDie cut acrylic tape is a specialized adhesive solution designed for precision applications in various industries, including automotive, electronics, and signage. This type of tape is crafted through a die-cutting process that allows for intricate shapes and sizes, tailored to specific design requirements. The acrylic adhesive used in these tapes is known for its strength, durability, and versatility, adhering effectively to a wide range of surfaces and withstanding various environmental conditions. The process involves applying the adhesive to an acrylic material, which is then cut into the desired shape, offering a clean and precise application. Ideal for mounting, bonding, or sealing, die cut acrylic tape provides a reliable and aesthetically pleasing solution. Its use ensures a strong bond, resistance to weathering, and longevity, making it a preferred choice for applications where quality and precision are paramount. For clients looking for a top-tier adhesive solution, die cut acrylic tape presents a superior option, aligning with high standards and diverse application needs.

-

Foam Tapes

Learn MoreDie-cut foam tapes are a versatile and innovative solution for various industries, offering unique properties that are ideal for customizing and enhancing product design and functionality. These tapes are crafted using a precision die-cutting process, allowing for intricate shapes and custom sizes to suit specific application needs. Made from materials like polyethylene or polyurethane foam, these tapes offer excellent cushioning, sealing, and vibration damping properties. They are frequently employed in automotive, electronics, and construction sectors, where a strong, reliable bond is essential. The use of automotive-grade polyurethane resin and 3M adhesive ensures a durable and long-lasting application, capable of withstanding harsh environments and stress. Die-cut foam tapes provide a solution that not only meets the technical requirements of a project but also contributes to the aesthetic and functional value of the final product, making them a crucial component in the design and manufacturing processes.

-

Double-Sided Tapes

Learn MoreDouble-sided tapes are a pivotal tool in various industries, offering the versatility and strength needed for bonding, mounting, and assembling applications. These tapes feature adhesive on both sides, making them ideal for invisibly attaching two surfaces together. They come in various types, including foam, acrylic, and tissue, each suited to different requirements and surfaces. Foam tapes provide cushioning and are excellent for uneven surfaces, while acrylic tapes offer strong bonding for applications requiring high durability and resistance to environmental factors. Tissue tapes, being thinner, are used where a less visible bond is needed. The choice of adhesive can be tailored to the specific conditions it will face, such as temperature ranges, exposure to chemicals, or UV light. Double-sided tapes are invaluable in sectors like automotive, construction, electronics, and signage, where they replace traditional fastening methods, providing a cleaner look and reducing material and labor costs. Their ease of application, coupled with their adaptability to various substrates, makes double-sided tapes an indispensable component in modern manufacturing and assembly processes.

-

Transfer Tapes

Learn MoreDie-cut transfer tapes are a testament to advanced adhesive technology, designed to meet the rigorous demands of various industries. These tapes are characterized by their lack of a carrier, featuring a robust, pressure-sensitive adhesive laid upon a removable release liner, which ensures a superior bond with minimal material thickness. Trailblazer specializes in customizing these tapes to precise specifications, facilitating their application across diverse sectors such as automotive, electronics, and medical devices. The tapes' versatility is underscored by their ability to adhere strongly to multiple substrates, maintain integrity under extreme temperatures, and offer chemical and UV resistance, making them an ideal choice for applications requiring durability and precision. This level of customization and performance underscores the value of die-cut transfer tapes in enhancing product design and assembly processes, demonstrating their pivotal role in modern manufacturing and engineering solutions.

-

Low Surface Energy Tapes

Learn MoreLow Surface Energy (LSE) adhesive tapes are meticulously engineered to address the challenge of bonding materials with inherently low adhesive receptivity, such as certain plastics and composites. These tapes are a cornerstone in industries requiring robust and durable adhesion without the traditional surface preparation methods. Standing at the forefront of utilizing these advanced adhesive solutions, offering custom die-cut LSE adhesive tapes that seamlessly integrate into various manufacturing processes. Our expertise not only facilitates the efficient application of these tapes but also enhances the design and functionality of the end products. With attributes like immediate handling strength that evolves to full bonding capacity, coupled with resistance to environmental stressors, LSE tapes provide a reliable bonding solution across a spectrum of applications, including automotive interiors and electronic devices, where precision and reliability are paramount.

-

Vibration Dampening Tapes

Learn MoreVibration dampening tapes are designed to mitigate structure-borne noise and reduce fatigue in metal and composite panels, enhancing the durability and performance of various applications. These tapes utilize a viscoelastic damping polymer, typically coated on a dead soft aluminum foil, to effectively dampen vibrations and control noise across a broad temperature range. Their peel-and-stick, pressure-sensitive nature allows for straightforward application, with the option for custom die-cut shapes to fit specific design requirements. Ideal for industries like aerospace, transportation, and electronics, these tapes not only improve the acoustic properties of materials but also contribute to the longevity and reliability of the components they are applied to.

-

Consumer Electronics

Learn MoreIn the consumer electronics market, die-cut tapes and adhesives are integral to device assembly and innovation. They are used to bond various components like displays, lenses, batteries, and frames, providing not just structural support but also contributing to the device's aesthetic appeal. These adhesives are selected for their strength, resistance to environmental factors, and ability to conform to complex shapes, ensuring that devices can withstand everyday use. From smartphones to wearables, die-cut adhesives help in sealing against moisture, enhancing impact resistance, and ensuring reliability in a range of temperatures, making them indispensable in the fast-evolving consumer electronics landscape.

-

Construction & Building

Learn MoreIn the construction and building industry, die-cut tapes and adhesives are revolutionizing the way contractors and builders approach their projects. These materials offer immediate bonding, enhancing energy efficiency and design freedom within structures. Unlike traditional fasteners like rivets and screws, die-cut tapes eliminate the need for drilling, which not only maintains the structural integrity but also streamlines the construction process, improving both aesthetics and efficiency. The versatility of these tapes extends to various applications, including roofing, window glazing, and HVAC systems, providing solutions that are both practical and innovative for modern construction challenges.

-

Automotive

Learn MoreIn the automotive industry, die-cut tapes and adhesives are integral to various applications, offering innovative solutions for bonding, assembly, and enhancement of vehicle components. These custom-cut materials replace traditional mechanical fasteners, providing a lightweight, aesthetically pleasing, and efficient alternative that enhances the durability and performance of automotive parts. From securing nameplates and trim to insulating and protecting electronic components, die-cut tapes and adhesives are used to reduce noise, vibration, and harshness (NVH), manage heat, and ensure the longevity of both interior and exterior elements. Their precision and customizability allow for seamless integration into automotive manufacturing, contributing to the vehicle's overall quality and reliability.

-

EMI Shielding Tapes

Learn MoreEMI shielding tapes play a pivotal role in safeguarding electronic devices from electromagnetic interference, ensuring their optimal performance and reliability. These tapes, crafted from materials like copper foil, are engineered to provide essential grounding and shielding for electronic enclosures and cables, enhancing the device's resistance to external electromagnetic noise. Offerings of die-cut EMI shielding tapes, which include variants like nickel on copper-plated polyester tapes, renowned for their flame retardancy and static discharge draining capabilities. Such tapes are indispensable in a myriad of applications, ranging from consumer electronics to sophisticated aerospace components, underscoring their versatility and critical function in the electronics industry.